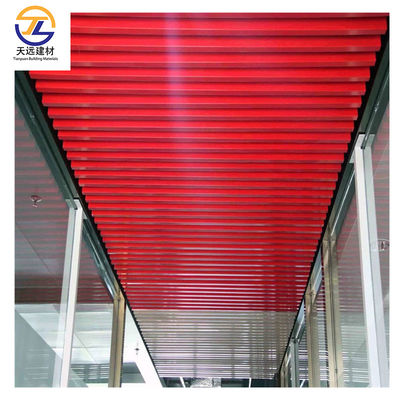

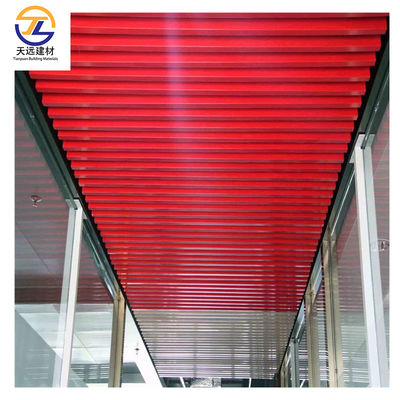

Fireproof Metal Aluminum Railing 60 X 60 Roof Aluminium Ceiling Tiles Humidity Resistance

Contact me for free samples and coupons.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Grid Ceiling | Application | Commercial Buildings |

|---|---|---|---|

| Ceiling Tile Type | Metal Ceilings | Moistureproof | Yes |

| Panel Thickness | 0.4 - 0.9mm | Fireproof Rating | Class A |

| Surface Treatment | Powder Coated | Humidity Resistance | 95% |

| Highlight | Fireproof Aluminum Railing,Metal Aluminum Railing 60 x 60,Roof aluminium ceiling tiles Humidity Resistance |

||

Fireproof Metal Aluminum Ceiling Tiles 60x60 Roof Tiles For biggest Building

Product Description:

AA1100, AA5005, and AA3003 aluminum cladding panels are engineered for architectural excellence, combining durability, aesthetics, and eco-efficiency. These panels are widely used in modern building facades, interior decor, and wood-grain-effect applications, offering a lightweight yet robust alternative to traditional materials. Backed by ISO 9001 and ASTM B209 certifications, they meet global standards for structural integrity and sustainability.

Quick Details:

1, Product Name: C-shaped Strip Ceiling

2, Perforate: 1.0, 1.8, 2.3mm round straight holes or plain

3, Edge profile: Beveled Edge/straight edge

4, Sound absorption: Germany soundtex, MRC0.65-0.8

5, Workmanship: Extrusion moulding forming

6, User type: Special size, kinds of punch, surface colors and assembly of installation, that could be to orders

7, Installation System: Black groove level type system and T-shaped carrier syste.

Advanced Manufacturing Process

Our aluminum cladding panels are produced under strict E-E-A-T guidelines to ensure quality and reliability:

Alloy Melting & Casting: High-purity aluminum ingots are melted and mixed with magnesium (AA5005) or manganese (AA3003) for enhanced properties.

Cold Rolling & Annealing: Precision cold-rolled to achieve uniform thickness, followed by annealing to eliminate internal stress.

Surface Treatment:

Wood-Grain Effect: Eco-friendly thermal transfer printing technology replicates realistic wood textures.

PVDF Coating: Anti-UV, scratch-resistant coating applied via electrostatic spraying for 20+ years of fade resistance.

Specification:

| Type | C-shaped ceiling strip | Supply Ability: |

5000 Square Meter/Square Meters per Week |

| Place of Origin: | Guangzhou, China | Usage: |

Interior/exterior; Indoor /outdoor

|

| Colors: | White/ RAL colors of choice | Lead Time: | Within 15-20 days |

| Thickness | 0.6-1.2mm | Size | 75mm,100mm,150mm,200mm,300mm |

| Surface Treatment |

Powder Coating/roll Coating |

Packing Details |

1. air bubble film+ wood crates 2. carton+plywood 3. accept customized package |

| Service |

Offer professional Advice,OEM&ODM |

Material suppliers | Southwest alu &German Aluimported |

| Product code: | N/A | Warranty: | 8-10years |

Advantages:

1, Multiple accessibility options;

2, Variety, pattern, color can be customized according to user requirements.

3, Good flatness, moisture resistance and oil resistance

4, Colorful, durable, non-fading,

5, C-shaped ceiling has a compact structure and seamless stitching, which can maintain no discoloration for 10 years;

6, Non-toxic, tasteless, environmentally friendly, 100% recyclable

7, Certificate: ISO9001:2008, ISO14001:2004, CE, SONCAP, GB/T28001-2011, SGS Test etc;

8, Custom made metal ceiling available to coordinate with ceilings and other interior / exterior finishings;

9, Easy & fast to install

Is an aluminium composite panel good?

Aluminium Composite Panels (ACP) are known for their exceptional strength and durability, thanks to the aluminium coils bonded on both sides. Available in a wide variety of colors and finishes, ACP sheets offer versatile design options. They are lightweight, easy to install, and are typically mounted onto aluminium framing systems—making the installation process significantly faster and more efficient compared to traditional stone cladding.

Types, Properties, and Applications of Aluminum Alloys (by Series)

1000 Series: Composition, Properties, and Applications

The 1000 series of aluminum alloys, also known as commercially pure aluminum, consists of alloys that are 99% or higher in aluminum content.

Composition

- Aluminum Content: 99% or higher.

- Typical Alloying Elements: Minimal amounts of silicon, iron, and other trace elements.

Properties

- Corrosion Resistance: Excellent due to high aluminum purity.

- Thermal and Electrical Conductivity: High, making these alloys suitable for electrical and thermal applications.

- Workability: Good, with excellent formability and ductility.

Applications

- Electrical Conductors: Utilized in power transmission lines and electrical cables.

- Chemical Processing Equipment: Due to their resistance to chemical corrosion.

- Food Packaging: Safe for food contact and resistant to spoilage.

- Heat Exchangers: Effective in transferring heat due to high thermal conductivity.

2000 Series: Composition, Properties, and Applications

The 2000 series alloys are primarily aluminum-copper alloys known for their high strength.

Composition

- Copper Content: About 2 – 10%.

- Other Elements: Small amounts of magnesium, manganese, and iron.

Properties

- Strength: High, making them suitable for demanding structural applications.

- Machinability: Good, allowing for ease of manufacturing complex parts.

- Corrosion Resistance: Lower compared to other series, often requiring protective coatings.

Applications

FAQ:

Q: What is the brand name of the Aluminum Metal Ceiling product?

A: The brand name is TianYuan.

Q: What is the model number of the Aluminum Metal Ceiling product?

A: The model number is TY-001.

Q: Where is the Aluminum Metal Ceiling product manufactured?

A: The product is made in China.

Q: What are the accepted payment terms for purchasing the Aluminum Metal Ceiling product?

A: The accepted payment terms are L/C and T/T.

Q: What is the price of the Aluminum Metal Ceiling product?

A: The price is USD15.7/m2.