Fireproof Artistic Aluminum Honeycomb Panel Square Aluminum Baffle Ceiling

Contact me for free samples and coupons.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Application | Hotel, Hospital, School, Interior Decoration | Size Of Panel | 1220*2440mm Or Custom Sizes |

|---|---|---|---|

| Product Category | Aluminum Honeycomb Panels | Color | Customized |

| Coating | PVDF/PE,or Without Coating Mill Finished | Function | Fireproof, Moisture-Proof, Mould-Proof, Smoke-Proof, Sound-Absorbing, Soundproof, Waterproof |

| Weather Resistance | Excellent | Advantage | Fireproof, Waterproof, High Strength |

| Highlight | Fireproof Aluminum Honeycomb Panel,Artistic Aluminum Honeycomb Panel,Square aluminium baffle ceiling |

||

Factory Direct Fireproof Artistic Square Tube Aluminum Baffle Ceiling Design

Quick Details:

Product Name:C-shaped Strip Ceiling

Perforation:1.0mm, 1.8mm, 2.3mm round straight holes or plain surface

Edge Profile:Beveled Edge / Straight Edge

Sound Absorption Performance:Using German Soundtex material, with a sound absorption coefficient of MRC 0.65 - 0.8

Workmanship:Extrusion Moulding

Customization for Users:Special sizes, various punching patterns, surface colors, and installation components can all accept customized orders

Installation System:Black Groove Horizontal Type System and T-shaped Carrier System

Specification:

| Type | C-shaped ceiling strip | Supply Ability: |

5000 Square Meter/Square Meters per Week |

| Place of Origin: | Guangzhou, China | Usage: |

Interior/exterior; Indoor /outdoor

|

| Colors: | White/ RAL colors of choice | Lead Time: | Within 15-20 days |

| Thickness | 0.6-1.2mm | Size | 75mm,100mm,150mm,200mm,300mm |

| Surface Treatment |

Powder Coating/roll Coating |

Packing Details |

1. air bubble film+ wood crates 2. carton+plywood 3. accept customized package |

| Service |

Offer professional Advice,OEM&ODM |

Material suppliers | Southwest alu &German Aluimported |

| Product code: | N/A | Warranty: | 8-10years |

![]()

Advantages:

1, Multiple accessibility options;

2, Variety, pattern, color can be customized according to user requirements.

3, Good flatness, moisture resistance and oil resistance

4, Colorful, durable, non-fading,

5, C-shaped ceiling has a compact structure and seamless stitching, which can maintain no discoloration for 10 years;

6, Non-toxic, tasteless, environmentally friendly, 100% recyclable

7, Certificate: ISO9001:2008, ISO14001:2004, CE, SONCAP, GB/T28001-2011, SGS Test etc;

8, Custom made metal ceiling available to coordinate with ceilings and other interior / exterior finishings;

9, Easy & fast to install

![]()

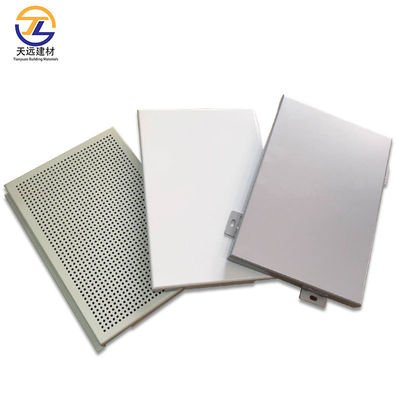

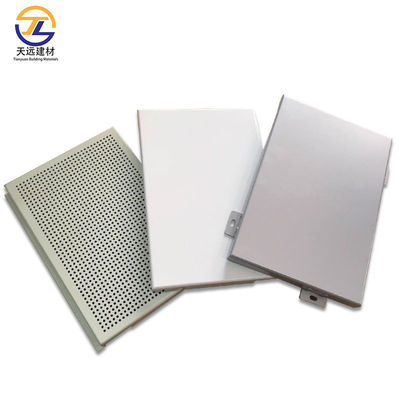

Fully Aluminum honeycomb sandwich composite panel with wooden textures and color

Descriptions of Aluminum Honeycomb Composite Panels

Weatherproof 3D wood grain aluminum fluted boards combine advanced material engineering with lifelike aesthetics, offering a resilient and visually striking solution for exterior walls, facades, and outdoor decorative applications. These high-density aluminum panels feature deep embossed wood textures and fluted designs, replicating natural timber while ensuring resistance to corrosion, UV radiation, and extreme weather conditions. Certified for ISO 9001 and ASTM standards, they meet global building codes for structural and environmental performance.

Composition of Aluminum Honeycomb Sandwich Panel

![]()

Why Use Aluminum Cladding?

Aluminum wall cladding is a material of choice in numerous configurations including single skin sheet, thicker solid aluminum plate, and aluminum composite material (ACM) consisting of two aluminum skins bonded to a solid fire-retardant core. There are a number of reasons why aluminum wall cladding is the preferred choice.

Advantages and Benefits of Aluminum Panels

![]()

Features

-

Material and Durability: Made from high-quality aluminum alloys such as AA1100, 3003, 3014, 5005, 5015, and 6063. These materials are lightweight yet strong, and they offer excellent corrosion resistance, ensuring a long lifespan.

-

Surface Treatment: Available in a variety of surface treatments, including anodizing, PVDF coating, powder coating, and options like stone and wood grain finishes. These treatments enhance both the appearance and the durability of the panels.

-

-

Thickness: The panels come in various thicknesses ranging from 0.5mm to 5.0mm, allowing for different levels of strength and rigidity based on the application.

-

![]()